Continuous Improvement Mastery

Building a Lean Factory with fully-funded CI training

Seize your factory’s potential through the government-funded Continuous Improvement Apprenticeships scheme. Train with industry experts for sustainable growth and enhanced productivity, with your own personalised training plans to advance your factory to it’s goals.

Services

What is an apprenticeship?

Apprenticeships provide individuals with the opportunity to learn job-specific skills and gain qualifications while working and earning a wage. Employers who pay the Apprenticeship Levy can have the training funded.

For Apprentices...

Why become an apprentice?

Becoming a continuous improvement apprentice is a strategic choice for professional growth. It offers hands-on learning, skill enhancement, the chance to contribute meaningfully to factory evolution, aligning personal development with organisational success.

For Employers...

Why appoint an apprentice?

Enrolling employees into a Continuous Improvement Apprenticeship injects fresh perspectives, fosters innovation, and inspires a culture of efficiency inside. From the training received, apprentices bring energy, adaptability, and a commitment to learning, driving continuous improvement across your factory.

Challenges

What are the specific issues you are facing?

The process to access the apprenticeship could not be easier. To get you set up our experienced admin team works closely to get the required information from you and liaise with the Scheme. Once you are set up you decide if you would like to be bespoke or co-mingled with other candidates.

All of this information and more is discussed in our CI Apprenticeship Webinar

1. Factory cost is almost always an issue!

Manufacturing the right product, at the right time, at the right cost is hard...

2. Is performance how you want it to be?

Output efficiency or waste causing frustrations? Solving problems permanently is difficult...

3. Improvement knowledge should be available to everyone

Specific tools and approaches make a real difference...

Apprenticeships Standards

What apprenticeships do we offer?

We offer 4 apprenticeship standards from yellow belt to black belt leader equivalent. These range in difficulty, from roughly A-Level to Masters. Open to all staff based in England with the relevant threshold education achievements.

All of this information and more is discussed in our CI Apprenticeship Webinar

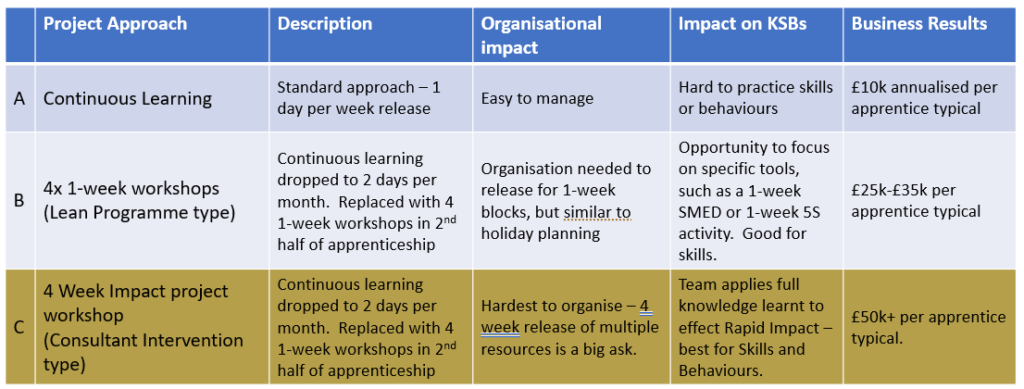

What Choices are there to make?

The training includes on-the-job and off-the-job learning. The length of the program varies based on the qualification being pursued, our standard are typically 12-14 months. The apprentice works alongside experienced staff, receives guidance and support from a mentor or supervisor, and gains practical skills, knowledge, and understanding of the industry.

All of this information and more is discussed in our CI Apprenticeship Webinar

Continuous Learning

Why is Continuous Improvement so important?

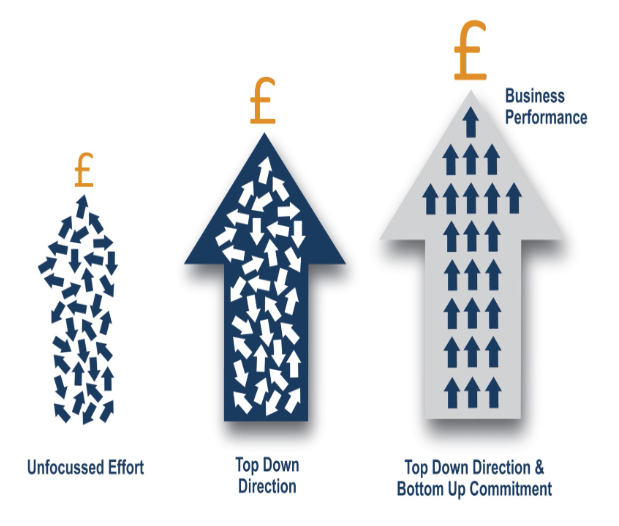

We believe in the inherent desire of individuals to excel at work. Given the right knowledge and opportunities, people actively contribute to business improvement. Emphasising ownership on the shop floor is paramount; sustained results emerge when the workforce takes charge of improvement initiatives, fostering a culture of continuous enhancement and shared success. As a member of the Register of Apprenticeship Training Providers (RoATP) since 2022, we stand at the forefront of shaping workforce development. Our identity is defined by a commitment to excellence, transformative training, and a legacy of driving substantial cost efficiencies for our esteemed clients on a global scale.

All of this information and more is discussed in our CI Apprenticeship Webinar

What Cohorts can you access?

Individual

Joint Cohort

Bespoke Cohort

Any

>£12k Levy Spend

>£36k Levy Spend

Courses starting in January, May, and September.

- Training Modules delivered at locations across the England.

- Skills support given by weekly 30 minute on-line meetings with the course Tutor

- Monthly wraparound support from a dedicated Development Coach.

- 2 Days on site support to ensure bespoke advice can be given.

OTJ Training plan is “Continuous Learning” only.

Team up with 2 other geographically close factories to make a “Joint Cohort”.

Rolling starts as agreed with other companies.

- Training Modules delivered at convenient location to your group.

- 10 days on site Skills support days. On-line skills support meetings with the course Tutor as required.

- Monthly wraparound support from a dedicated Development Coach.

- Site initation visit, and bespoke course design.

OTJ Training plan can be either “Continuous Learning” only, or “Lean Workshops”. Bespoke design.

Rolling starts, whenever suits you.

- Training Modules delivered on site or at aconvenient location close by.

- 30 days on site Skills support days. On-line skills support meetings with the course Tutor as required.

- Monthly wraparound support from a dedicated Development Coach.

- Site initation visit, bespoke course design, Project identification included.

OTJ Training plan can be either “Continuous Learning” only, “Lean Workshops”, or “Impact Workshop”.

Bespoke design.

All of this information and more is discussed in our CI Apprenticeship Webinar

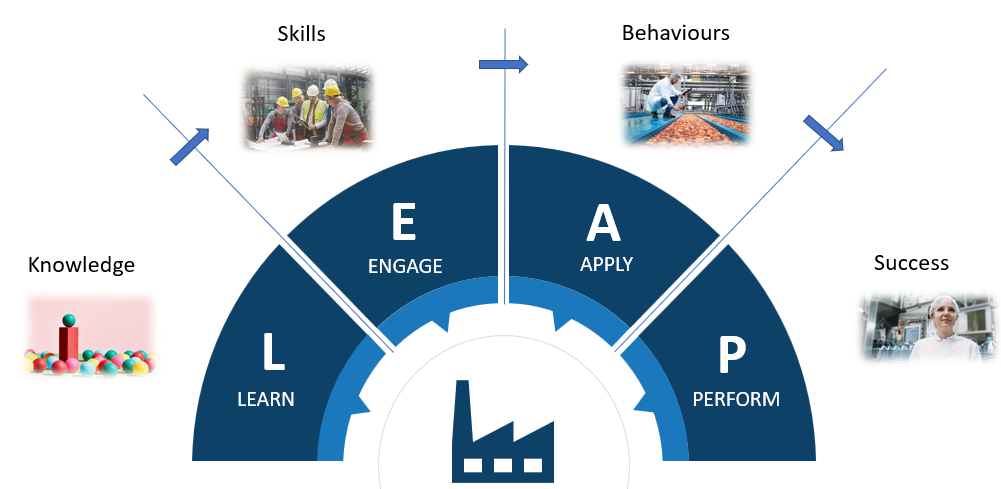

LEAP Training Model

Game Based Modular Knowledge Training

Practical Skills Teaching

Long Term Behaviours Support

Recognised Lean and Apprenticeship Qualification

All of this information and more is discussed in our CI Apprenticeship Webinar

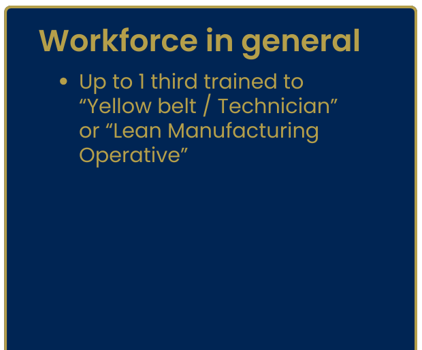

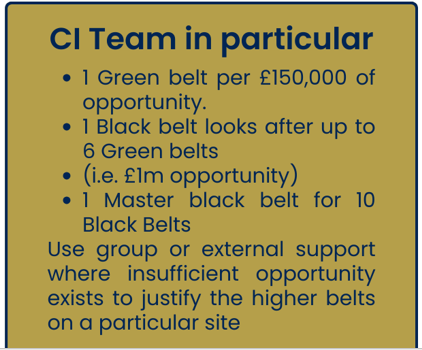

What should a CI Team look like?

CI is everybody’s job. Same way that quality is everybody’s job.

Just as with quality, CI needs a bespoke function with subject matter experts who drive and measure the CI agenda, and assure results

All of this information and more is discussed in our CI Apprenticeship Webinar

What are the benefits of an Apprenticeship?

Our Continuous Improvement Apprenticeships span for 14 months, incorporating an immersive practical phase, coupled with a meticulous 3-month end-point assessment. The training is methodically tailored, addressing apprentice needs identified through an initial skill scan. These training plans, while being individually specific, place a pronounced emphasis on honing skills in supply chain optimisation, proficiency in data analytics, and mastery of lean manufacturing principles. This strategic focus ensures that apprentices not only gain practical experience but also cultivate expertise in pivotal industry practices, positioning them for success in their careers.

All of this information and more is discussed in our CI Apprenticeship Webinar

Services

How can the apprenticeship scheme be accessed?

The process to access the apprenticeship could not be easier. To get you set up our experienced admin team works closely to get the required information from you and liaise with the Scheme. Once you are set up you decide if you would like to be bespoke or co-mingled with other candidates.

All of this information and more is discussed in our CI Apprenticeship Webinar

1. Submit Candidates

Produce a list of candidates (min of 2) with their preferred apprenticeship course choices.

2. Eligibility Check

Prior learnings. Benchmark Maths, and English. Candidate is based in England and has the right to work.

3. Confirm Cohorts

Confirm; candidate, course, and group. Option to train alone or co- mingled with other companies.

4. Start Program

Work with our onboarding team to start the apprenticeship journey.

Programme Management

E-Portfolio

Monthly Development Coach meetings

Supported Skills / Project Days

Monthly Management RAG Report

Line Manager Engagement

12 Weekly Sponsor Reviews

About

LI Factory Excellence

Over the last 18 years we have supported more than 120 factories and trained over 1500 factory staff. Our clients cover a wide range of manufacturers, including Cadbury, Weetabix, and Reckitt Benckiser. We have advised 20+ private equity deals totalling over £4bn deal value. LI Europe are Gold standard IIP, are a Government recognized apprenticeship training provider and regularly talk on factory improvement.

Our Clients

Get In touch

Leave us a message

7517 Comstock Ln, Darien, IL, 60561

LI Factory Excellence

Unit 4, The Stables, Boroughbridge Rd, Newby Hall, Ripon HG4 5AE

Tel 0333 456 1988